Forging a Sustainable Path: A Synergy of Expertise

In the domain of waste management, the partnership between CCI and BTA stands as a beacon of innovation, efficiency, and sustainability. This collaboration is geared towards reshaping the landscape of Anaerobic Digestion (AD) with a commitment to excellence. At its core lies a shared dedication to optimizing the waste-to-energy journey, aligning technological prowess with environmental consciousness.

Forging a Sustainable Path: A Synergy of Expertise

In the domain of waste management, the partnership between CCI and BTA stands as a beacon of innovation, efficiency, and sustainability. This collaboration is geared towards reshaping the landscape of Anaerobic Digestion (AD) with a commitment to excellence. At its core lies a shared dedication to optimizing the waste-to-energy journey, aligning technological prowess with environmental consciousness.

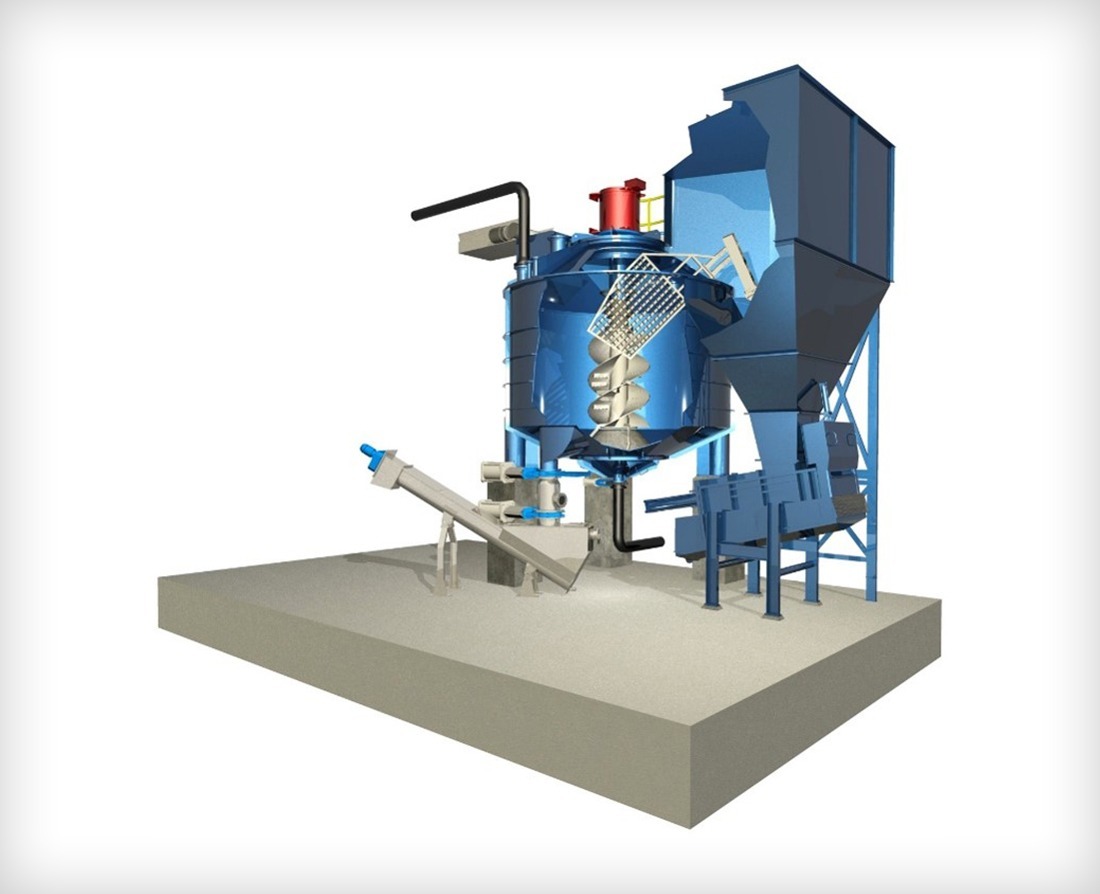

Pioneering Waste Pre-Treatment with the BTA® Process

In the intricate tapestry of waste pre-treatment, the BTA® Waste Pulper emerges as a pivotal cornerstone. This component encapsulates the essence of wet mechanical waste pre-treatment, orchestrating functions that pave the path for optimal biogas production. By amalgamating dissolution, defibration, and meticulous separation, the BTA® Waste Pulper surmounts challenges posed by diverse waste compositions.

Noteworthy Attributes

Discerning Fraction Separation:

The BTA® Waste Pulper's acumen lies in its precise ability to categorize waste into light and heavy fractions, curbing organic contamination

Resilience against Contaminants:

With an exceptional capacity to manage contamination levels of up to 50%, the pulper redefines efficiency within waste processing.

Safeguarding Plastics Integrity:

Departing from conventional methods that lead to plastics fragmentation, the BTA® process safeguards plastics, mitigating wear in the AD system.

Enhanced Digestion Efficiency:

Through meticulous defibration, an organic suspension with an augmented surface area is realized, optimizing biogas production.

Versatility across Diverse Waste Categories:

From medical waste to pet-derived residuals, the BTA® Waste Pulper accommodates an extensive spectrum of waste materials.

Uninterrupted Automated Operation:

Operating ceaselessly with precision, the system obviates the need for manual intervention, ensuring operational reliability.

Proven Robustness over Decades:

Systems commissioned as far back as 1994 continue to function seamlessly, testifying to the BTA® Waste Pulper's enduring strength.

Noteworthy Attributes

Discerning Fraction Separation:

The BTA® Waste Pulper's acumen lies in its precise ability to categorize waste into light and heavy fractions, curbing organic contamination

Resilience against Contaminants:

With an exceptional capacity to manage contamination levels of up to 50%, the pulper redefines efficiency within waste processing.

Safeguarding Plastics Integrity:

Departing from conventional methods that lead to plastics fragmentation, the BTA® process safeguards plastics, mitigating wear in the AD system.

Enhanced Digestion Efficiency:

Through meticulous defibration, an organic suspension with an augmented surface area is realized, optimizing biogas production.

Versatility across Diverse Waste Categories:

From medical waste to pet-derived residuals, the BTA® Waste Pulper accommodates an extensive spectrum of waste materials.

Uninterrupted Automated Operation:

Operating ceaselessly with precision, the system obviates the need for manual intervention, ensuring operational reliability.

Proven Robustness over Decades:

Systems commissioned as far back as 1994 continue to function seamlessly, testifying to the BTA® Waste Pulper's enduring strength.

The Rigorous Art of Sediment Separation: The BTA® Grit Removal System

In waste treatment, the BTA® Grit Removal System emerges as a groundbreaking solution. Its cardinal objective is to address the challenge posed by sand, glass, and steel particles, mitigating the effects these constituents impose on equipment. By liberating the organic suspension from sedimentable impurities, this system alleviates maintenance concerns and enhances operational efficiency.

Key Characteristics

- Precision-Centric Sediment Separation: The hydrocyclone, classifying tube, and grit box yield a methodical separation process, culminating in a separation rate surpassing 98%.

- Grit-Free Digesters: Digesters interwoven with the BTA® Grit Removal System showcase a decade of operation devoid of grit accumulation, reducing wear within pumps and pipelines.

- Purity Assurance: The BTA® Grit Removal System assures a contaminant-free digestate, underscoring the quality of the ultimate product.

Key Characteristics

- Precision-Centric Sediment Separation: The hydrocyclone, classifying tube, and grit box yield a methodical separation process, culminating in a separation rate surpassing 98%.

- Grit-Free Digesters: Digesters interwoven with the BTA® Grit Removal System showcase a decade of operation devoid of grit accumulation, reducing wear within pumps and pipelines.

- Purity Assurance: The BTA® Grit Removal System assures a contaminant-free digestate, underscoring the quality of the ultimate product.

A Testimonial to Expertise: The BTA® Process - A Legacy of Innovation

The core components and comprehensive framework of the BTA® Process stand fortified by international patents and trademark rights. Clients can rest assured that embracing the BTA® Process aligns them with technology that has evolved over decades. Our clients gain from an original and trailblazing solution.

An Oath to Quality

By embracing the BTA® Process, clients adopt technology that has evolved over decades and align themselves with a solution underpinned by international patents and trademark rights. This commitment to quality underscores our dedication to delivering solutions that elevate waste management to a new level of sophistication and effectiveness.

An Oath to Quality

By embracing the BTA® Process, clients adopt technology that has evolved over decades and align themselves with a solution underpinned by international patents and trademark rights. This commitment to quality underscores our dedication to delivering solutions that elevate waste management to a new level of sophistication and effectiveness.