Anaerobic Digestion (AD) Unveiled: Mastering Organic Metamorphosis

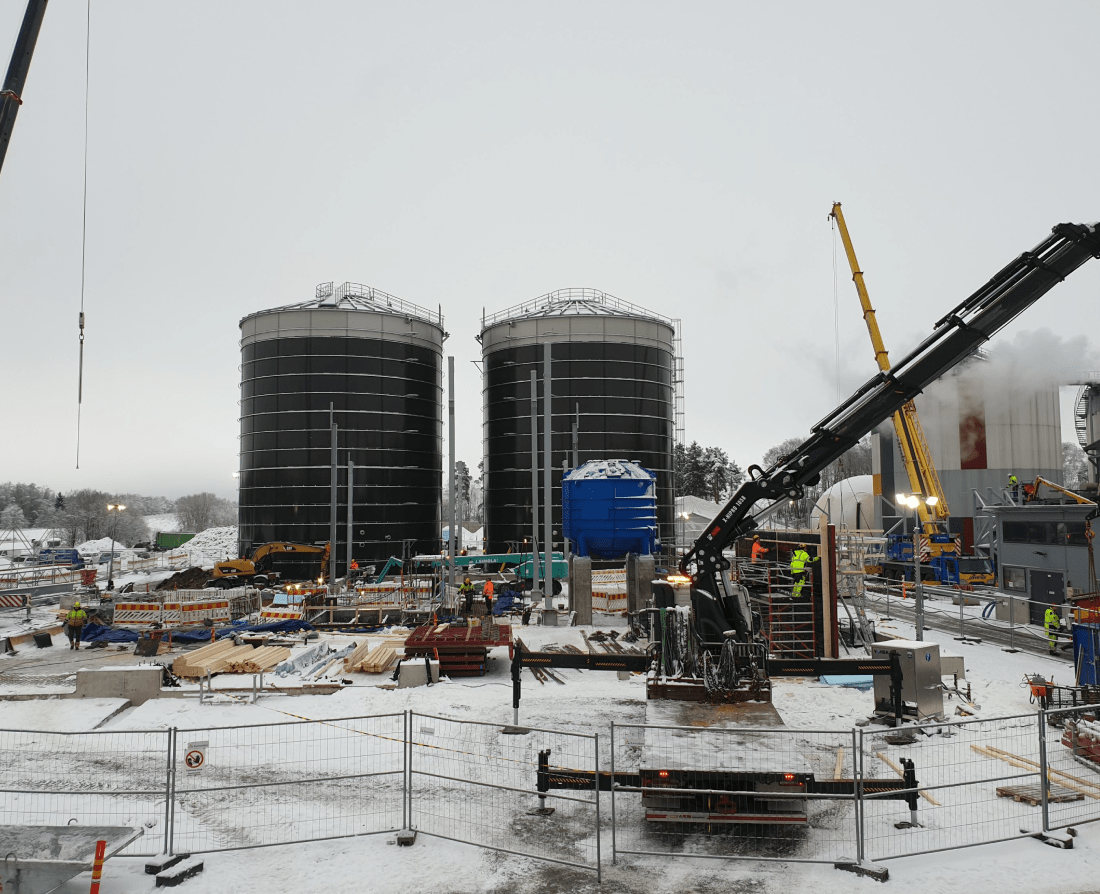

The AD voyage embarks with the refined biosuspension finding a temporary home within a suspension tank. This strategic decoupling bridges treatment from fermentation, allowing the latter to unfold autonomously regardless of waste reception dynamics. Powered by fully mixed fermenters, the organic suspension takes its transformative journey through fermentation. Often adopting a mesophilic approach within a single-stage design, these fermenters maintain temperatures of 35 - 38°C. The fermenter's blueprint and operational strategies seamlessly intertwine with the unique feedstock attributes and the specific requisites of microbiological breakdown and biogas production.

Anaerobic Digestion (AD) Unveiled:

Mastering Organic Metamorphosis

The AD voyage embarks with the refined biosuspension finding a temporary home within a suspension tank. This strategic decoupling bridges treatment from fermentation, allowing the latter to unfold autonomously regardless of waste reception dynamics. Powered by fully mixed fermenters, the organic suspension takes its transformative journey through fermentation. Often adopting a mesophilic approach within a single-stage design, these fermenters maintain temperatures of 35 - 38°C. The fermenter's blueprint and operational strategies seamlessly intertwine with the unique feedstock attributes and the specific requisites of microbiological breakdown and biogas production.

Harnessing Synergy: Tailored Mixing

Possibilities

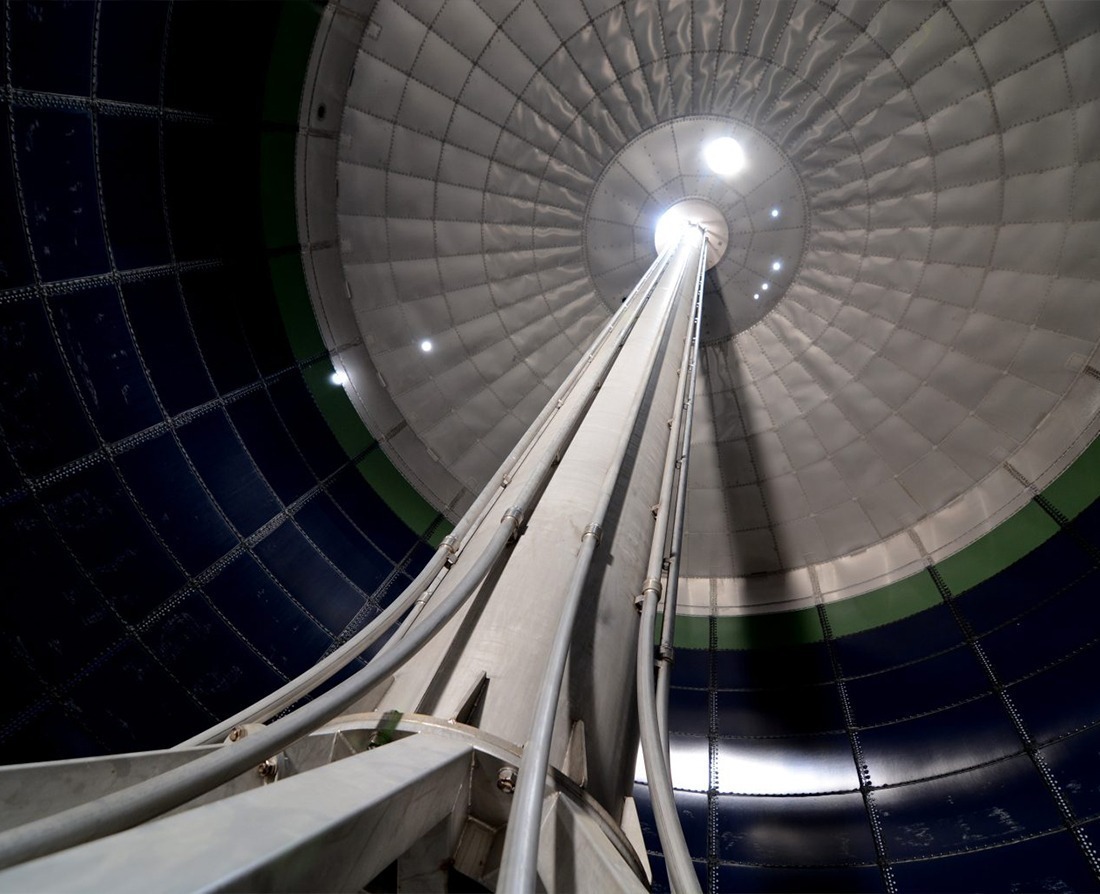

In the realm of fermenter agitation, a common challenge emerges in various AD systems. However, the BTA® Process introduces a refined mechanism, ensuring a harmonious and resolute organic suspension. Relying on waste specifications, we meticulously select the most fitting mixing approach. For products rich in fibrous content, we deploy a biogas mixing mechanism, characterized by a bottom-to-top flow pattern. Conversely, for substances prone to floating particles, top mixing with a top-to-bottom flow pattern is embraced. The overarching objective persists: to pinpoint the optimal technology for your waste. This bespoke approach ensures the earlier outlined outcomes are actualized while seamlessly aligning with your waste's unique attributes

This strategic enhancement leverages controlled mixing mechanisms tailored to each waste's distinct properties. This approach resonates profoundly:

- Equitable Circulation: A rhythmic circulation pattern envelops the fermentation chamber, preserving equilibrium.

- Nurturing Microcosm: A conducive habitat for microorganisms to flourish, fostering optimal efficiency.

- Energy Efficiency: Resource inputs are deftly managed, leading to elevated utilization efficiency.

- Mechanical Ingenuity: The fermenter houses no internal moving components, ensuring robustness.

- Minimal Upkeep: The fermenter’s interior demands minimal maintenance, streamlining operations.

This strategic enhancement leverages controlled mixing mechanisms tailored to each waste's distinct properties. This approach resonates profoundly:

- Equitable Circulation: A rhythmic circulation pattern envelops the fermentation chamber, preserving equilibrium.

- Nurturing Microcosm: A conducive habitat for microorganisms to flourish, fostering optimal efficiency.

- Energy Efficiency: Resource inputs are deftly managed, leading to elevated utilization efficiency.

- Mechanical Ingenuity: The fermenter houses no internal moving components, ensuring robustness.

- Minimal Upkeep: The fermenter’s interior demands minimal maintenance, streamlining operations.

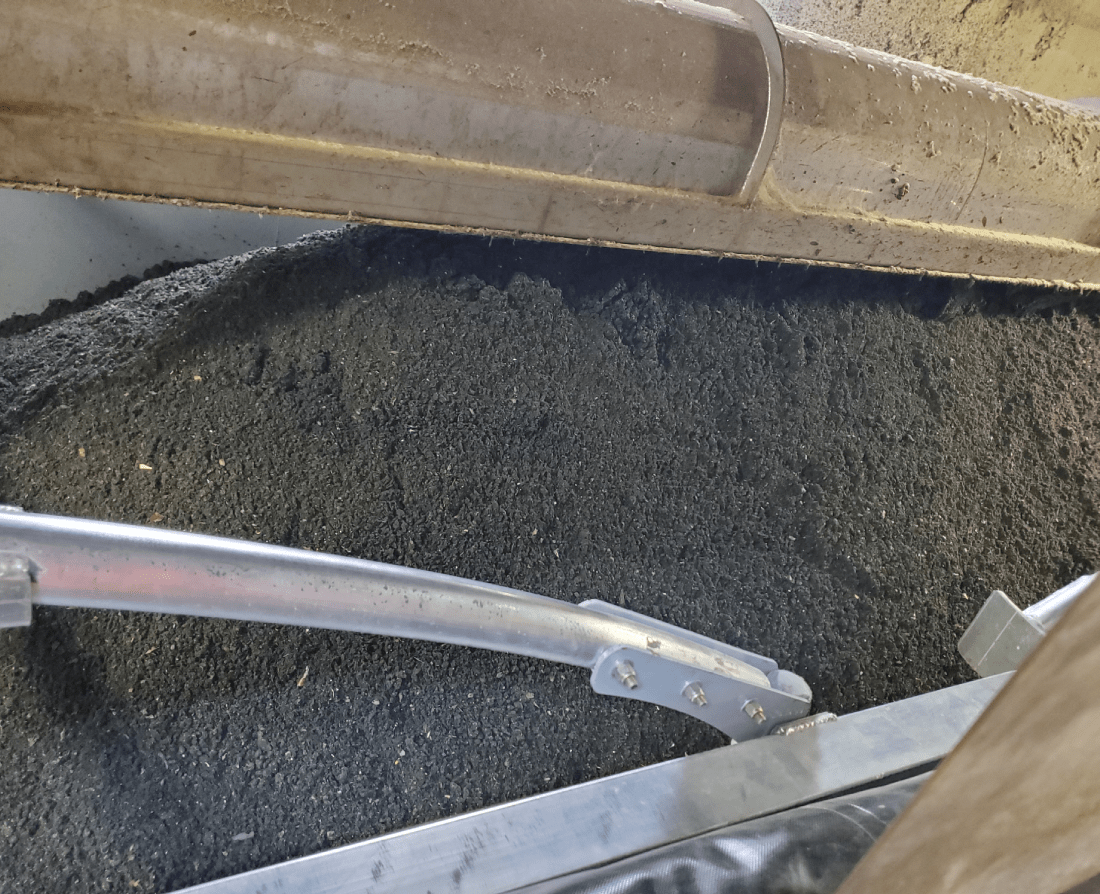

Charting the Digestate's Evolution

The digestate's trajectory takes a transformative path, molded by project-specific intricacies. Based upon the client's requirements, we can design a system that pasteurizes the digestate and utilizes it as a liquid fertilizer, or we can employ a thickening approach. The thickening process employs centrifuges or screw presses to orchestrate solid-liquid separation. The outcome produces a dewatered digestate with a dry matter content hovering around 30%. This organic cake is stored for further refinement, contributing to the formulation of quality compost. Liquids from the thickening step can be integrated within the process serving as process water, fostering a closed-loop sustainability model by curbing fresh water usage, or undergo cleaning in a waste water treatment plant. This orchestrated process exemplifies efficient resource management. Ultimately, our design adapts seamlessly to meet the client's unique needs.

Embrace a Future of Sustainable Transformation with CCI and BTA

As pioneers in the realm of Anaerobic Digestion (AD), the combined forces of CCI and BTA create an unmatched synergy, dedicated to revolutionizing waste management. With CCI’s profound expertise in environmental engineering and BTA’s cutting-edge technology, we offer a comprehensive solution that encompasses every facet of the waste-to-energy journey. Together, we pave the way for a greener tomorrow, offering unrivaled innovations that harmonize with nature, optimize resource utilization, and foster a world where sustainable transformation is not just a concept, but a reality. Join us in this transformative journey, where innovation meets commitment, and waste finds its purpose anew.

Embrace a Future of Sustainable Transformation with CCI and BTA

As pioneers in the realm of Anaerobic Digestion (AD), the combined forces of CCI and BTA create an unmatched synergy, dedicated to revolutionizing waste management. With CCI’s profound expertise in environmental engineering and BTA’s cutting-edge technology, we offer a comprehensive solution that encompasses every facet of the waste-to-energy journey. Together, we pave the way for a greener tomorrow, offering unrivaled innovations that harmonize with nature, optimize resource utilization, and foster a world where sustainable transformation is not just a concept, but a reality. Join us in this transformative journey, where innovation meets commitment, and waste finds its purpose anew.