Revolutionizing Mixed Solid Waste (MSW) Organics Processing

At CCI Bioenergy, we take immense pride in our partnership with BTA International GmbH, a pioneer in wet-mechanical processing solutions. Together, we are revolutionizing the treatment of Mixed Solid Waste (MSW) organics, offering cutting-edge technology that maximizes efficiency and sustainability.

Revolutionizing Mixed Solid Waste (MSW) Organics Processing

At CCI Bioenergy, we take immense pride in our partnership with BTA International GmbH, a pioneer in wet-mechanical processing solutions. Together, we are revolutionizing the treatment of Mixed Solid Waste (MSW) organics, offering cutting-edge technology that maximizes efficiency and sustainability.

Handling Challenging Waste Streams with Ease

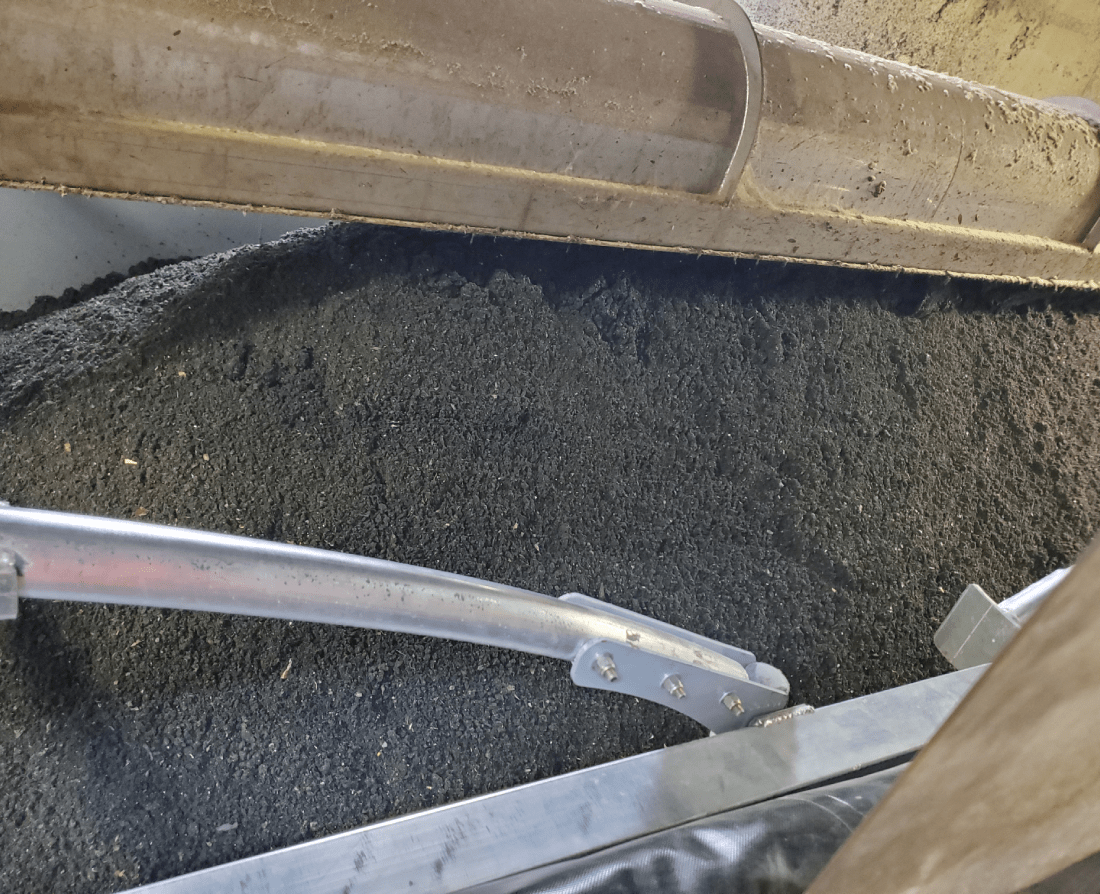

Thanks to the exceptional degree of contaminant separation achieved through BTA’s wet-mechanical processing, we can unlock the potential of organic fractions from household waste or residual waste. Our technology boasts remarkable insensitivity to high levels of impurities, ensuring uninterrupted operations and high availability. This makes the BTA® process an ideal solution for Mechanical Biological Treatment (MBT) facilities that incorporate an anaerobic digestion stage.

The screened MSW undergoes the BTA® Hydromechanical Pre-Treatment, efficiently removing impurities and recovering digestible organic components. This organic suspension is then processed in the subsequent anaerobic digestion step.

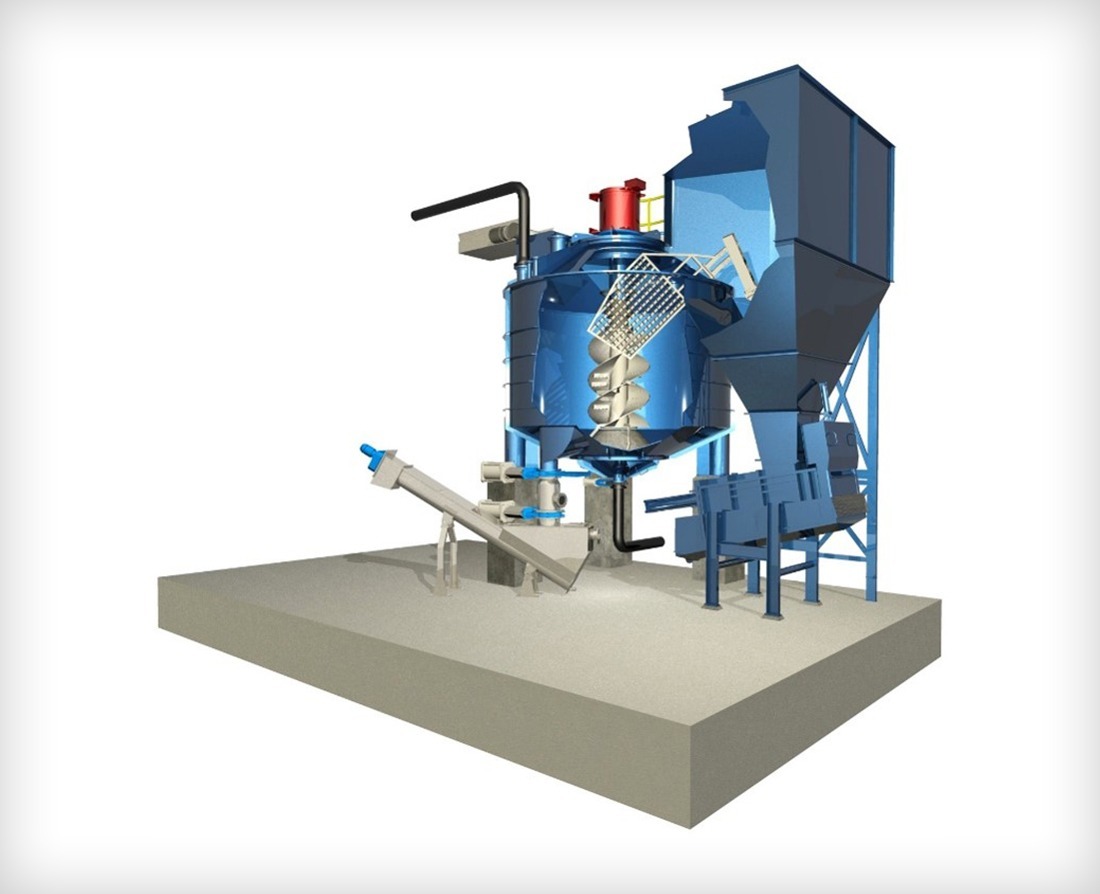

Advanced Wet Pre-Treatment Design

At the heart of the wet pre-treatment process lies BTA® Waste Pulpers, LRS Screw units, presses, heavy fraction traps, classifiers, and Grit Removal Systems. These cutting-edge components, provided by BTA International GmbH, ensure optimal separation of light, heavy, and grit fractions from the waste stream, enhancing the overall process efficiency.

Advanced Wet Pre-Treatment Design

At the heart of the wet pre-treatment process lies BTA® Waste Pulpers, LRS Screw units, presses, heavy fraction traps, classifiers, and Grit Removal Systems. These cutting-edge components, provided by BTA International GmbH, ensure optimal separation of light, heavy, and grit fractions from the waste stream, enhancing the overall process efficiency.

Unlocking Biogas Potential and Quality Compost

Thanks to the BTA hydromechanical pulper’s almost complete dissolution of the fermentable organic matter, optimal fermentation and full utilization of the biogas potential are achieved. Furthermore, our wet-mechanical processing excels in separating impurities with high efficiency, enabling the production of quality compost from the fermentation residue without costly post-processing. The unique substrate flexibility of the BTA® process serves as an additional advantage, contributing to the long-term economic success of your plant.

A Sustainable Approach

At CCI Bioenergy, we are dedicated to sustainable practices. As part of our commitment to reducing environmental impact, we work closely with BTA International to implement a process design for removing suspended solids from a partial stream of the liquid digestate. This produces the vital “Process Water,” used for rinsing purposes in the hydromechanical pre-treatment. This not only reduces the demand for potable water but also minimizes excess water generation.

A Sustainable Approach

At CCI Bioenergy, we are dedicated to sustainable practices. As part of our commitment to reducing environmental impact, we work closely with BTA International to implement a process design for removing suspended solids from a partial stream of the liquid digestate. This produces the vital “Process Water,” used for rinsing purposes in the hydromechanical pre-treatment. This not only reduces the demand for potable water but also minimizes excess water generation.

Unmatched Expertise in MBT Technology

With multiple facilities already operating successfully with BTA Technology, this venture highlights our leadership in pre-treatment and anaerobic digestion of the Organic Fraction from Municipal Solid Waste.